When comfort swings with the weather, a lifecycle mindset keeps you ahead. Start by mapping what matters: airflow, insulation, room usage, and your daily routine. Then line up fast wins, followed by bigger upgrades, so each step builds value. Treat it like a simple routine you can follow without stress. We’ll explore how to plan smart, choose the right parts, and schedule work without disrupting life. You’ll see how routine checks prevent surprises and how clean systems run quieter. We’ll also cover how to weigh cost, quality, and timing when budgets are tight. For homeowners and light commercial spaces, simple tools and clear rules make measured progress. Use practical checklists and quick tests to spot small issues before they grow. If you’re comparing options, fold in installation and maintenance as a package, not a patchwork. That way, upgrades match your goals, timelines, and the way people actually use the space.

Map scope early with simple goals and zone-by-zone needs defined

Start with a quick walk-through to spot heat spikes, cold corners, and noisy runs. installation and maintenance

Use colored tape to mark grills that feel weak, and note doors that stick from pressure swings. Draft a short list that ranks the worst comfort issues. Aim for no more than a 2–3 degree drift from room to room. Include notes on sound levels and the filter sizes you need. Confirm the electrical panel capacity before planning add-ons. These small steps reduce callbacks. If a shop is busy, run checks before opening hours.

Agree on simple success metrics—temperature range, noise, and airflow—before any tools come out. A small clinic, for example, may prioritize quiet over speed in exam rooms, while the back office prefers stronger airflow. List constraints like hours of access, stair-only delivery, and parking limits. Plan a mid-scope review and a final scope review to avoid surprises. With a clear path, you can phase improvements without confusion.

Choose right-sized parts, clean filters, and reliable accessories that fit

Match blower capacity to duct size, not just square footage, for better balance. installation and maintenance

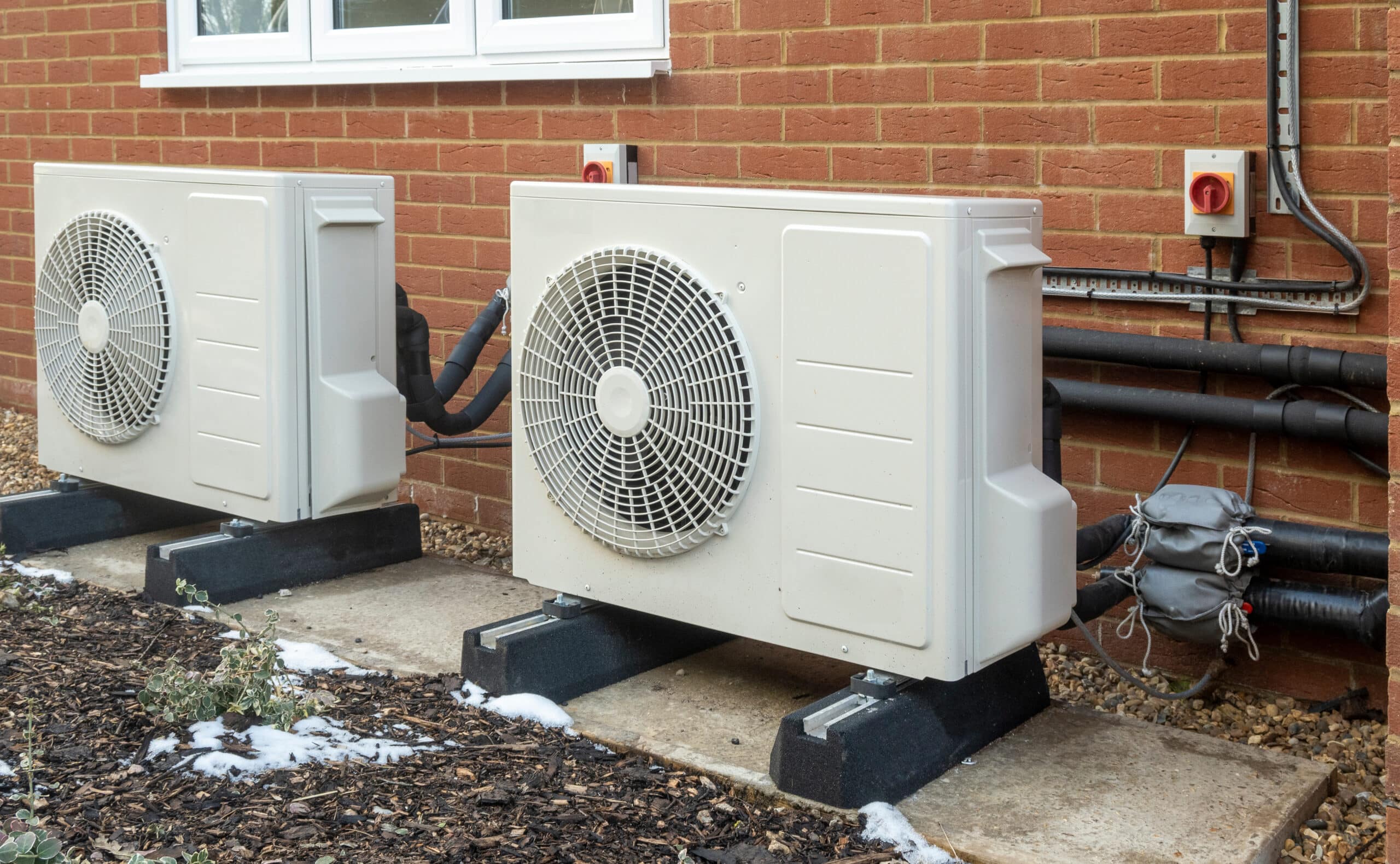

Select filter ratings that capture dust but keep air moving. Use foil tape instead of cloth tape on seams. Add rubber isolation pads under equipment to tame vibration. If zoning is needed, choose dampers with clear position indicators. A small office might use smart stats to trim after-hours waste. Pilot one zone before you scale the same parts elsewhere.

Choose components with widely available replacements to prevent long waits. In a retail bay, a mismatched return size can whistle and reduce comfort at the front register. Measure duct static with a simple manometer to confirm your picks. Favor bigger filter area rather than jumping to a denser rating. These selections keep systems stable and reduce wear over time.

Build a realistic schedule, lock tasks in order, and stage work

Map tasks by dependencies: inspection, sealing, test, then controls and trims. installation and maintenance

Push loud work to early mornings or evenings for quiet. Time deliveries one day ahead to prevent idle crews. Label each task with a time estimate and two backups. Share a single-page schedule with tenants or staff. This pace limits rework and keeps days predictable. For early work, verify door times and alarm codes by Thursday.

Hold quick morning check-ins to spot delays and reshuffle as needed. A property manager might greenlight duct sealing on Tuesday, leaving Friday for balance tests and control tuning. Color-code tasks by crew so no one waits on another team. Include slack time near testing to absorb retests. Clear sequencing prevents last-minute scrambles and keeps quality steady.

Raise quality, control risk, and verify results with simple tests

Start with baseline data: room temps, return and supply delta, and noise readings. AC repair

Photograph filters and coil faces before cleaning for proof and comparison. Use a handheld smoke pen to find duct leaks. Record total static changes to confirm sealing did its job. Label cleared drains with date and initials. In small apartments, a 3-degree improvement feels big to tenants. Schedule verification checks before you close the ticket.

If a check fails, trace the cause instead of masking it. That’s how AC repair avoids repeat visits after a hot weekend. Rule out return restrictions and dirty filters before deeper steps. Confirm thermostat calibration against a known-good thermometer. These steps make quality predictable and repeatable across jobs.

Balance cost, weigh trade-offs, and pick upgrades with evidence

Rank improvements by the quickest comfort gain per dollar spent. installation and maintenance

Seal obvious leaks first, then resize returns where pressure runs high. Choose smart controls only if schedules are stable. Price out filter area increases before jumping to pricier media. Group tasks so setup and cleanup happen just once. In a café, a quiet motor may be worth a slight delay. Reserve a small budget slice for unknowns.

Watch utility bills the next month to validate savings. A four-unit building might see faster payback from sealing and balancing than from new gear. When funds are limited, sequence upgrades by the busiest areas. Weigh dollars against comfort, sound, and upkeep effort. This method keeps spending focused and results visible.

Plan upkeep that lasts, with annual routines and simple roles

Make a maintenance calendar tied to seasons and usage patterns. installation and maintenance

Swap filters on fixed dates so no one guesses. Flush condensate lines at the start of cooling season. Vacuum return grills and check door gaps that change pressure. Tape a simple checklist near the unit with names and times. In salons, hair dust means more frequent filter checks. Small, steady tasks prevent larger breakdowns when demand peaks.

Assign who does what: on-site staff handles simple checks; pros tackle technical items. A community center might train volunteers to swap filters and wipe coils while pros handle deeper service. Use phone reminders that ping the team before monthly tasks. Tune the schedule every quarter to match real-world conditions. With routines in place, comfort stays steady as seasons change.

In the end, planning, parts selection, scheduling, verification, and steady care work together. Layered improvements deliver stable comfort and fewer surprises. Pick routines you can track, and refine them as you learn. With this approach, you can move from quick fixes to durable results without guesswork.